- 2024-11-27 07:30:40

- source: 本站

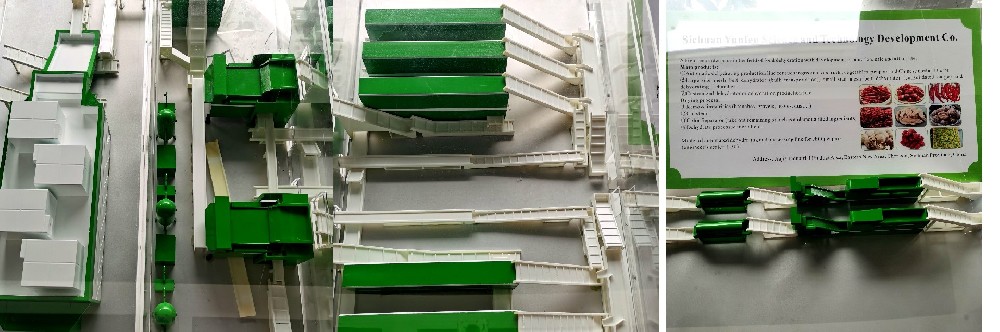

Streamlining Food Processing with Industrial Dehydrators

Food processing faces numerous challenges, from maintaining nutritional value and extending shelf life to managing large volumes of produce efficiently. Traditional methods often fall short, leading to spoilage, inconsistent quality, and labor-intensive processes. Industrial food dehydrators offer a compelling solution, addressing these difficulties and optimizing various aspects of food processing.

Preserving Nutritional Value and Enhancing Flavor

One major challenge in food processing is preserving the nutritional value of ingredients. Dehydration, when done correctly, can actually concentrate nutrients. By removing water, the concentration of vitamins, minerals, and antioxidants increases per unit weight. Our industrial dehydrators offer precise temperature and airflow control, crucial for minimizing nutrient loss during the drying process. This controlled environment also helps to retain and even enhance the natural flavors of the food, resulting in a more intense and desirable taste profile.

Extending Shelf Life and Reducing Food Waste

Spoilage is a significant concern in the food industry. Industrial dehydrators tackle this issue by drastically reducing water activity, inhibiting microbial growth and enzymatic reactions that cause decay. This significantly extends the shelf life of products, minimizing waste and reducing the need for costly preservation methods like freezing or canning. The extended shelf life also opens up new markets and distribution possibilities.

Efficiently Handling High Volumes and Diverse Products

Our industrial dehydrators are designed to handle large quantities of produce quickly and efficiently. The customizable nature of our machines, from conveyor belt sizes to drying chamber configurations, allows for seamless integration into existing production lines. Whether processing chili peppers, ginger, onions, fruits, vegetables, or meat, our dehydrators can be tailored to specific product requirements. This flexibility ensures optimal drying performance for a diverse range of ingredients.

Reducing Labor Costs and Improving Processing Speed

Traditional drying methods are often labor-intensive, requiring manual handling and monitoring. Our automated industrial dehydrators significantly reduce labor requirements. The automated systems control temperature, airflow, and drying time, minimizing manual intervention and freeing up personnel for other tasks. The faster drying times achieved with these machines further improve processing speed, increasing overall production efficiency.

Maintaining Consistent Quality and Hygiene Standards

Maintaining consistent quality across large batches of product can be a major challenge. Industrial dehydrators offer a controlled and uniform drying environment, ensuring consistent moisture levels and product quality. The enclosed design of our dehydrators also minimizes the risk of contamination, adhering to stringent hygiene standards crucial for food safety.

Customization and Support for Specific Needs

We understand that every food processing operation has unique requirements. That's why we offer customized industrial dehydration solutions tailored to specific needs and production scales. Our team of experts works closely with clients to design and implement systems that integrate seamlessly into their existing workflows. We also provide comprehensive after-sales support, ensuring optimal performance and longevity of our equipment.

Cost-Effective Solution for Long-Term Savings

While the initial investment in an industrial dehydrator might seem significant, the long-term benefits outweigh the costs. Reduced spoilage, lower labor costs, increased production efficiency, and expanded market opportunities contribute to significant long-term savings, making industrial dehydration a cost-effective solution for modern food processing.

Investing in the Future of Food Processing

Industrial food dehydrators represent a significant advancement in food processing technology. They address critical challenges, improve efficiency, and enhance product quality. By investing in our industrial dehydrators, businesses are investing in the future of food processing, securing a competitive edge and contributing to a more sustainable and efficient food system.