- 2024-12-04 22:30:10

- source: 本站

Advancements in Automation for Industrial Food Dehydration Processes

The evolution of industrial food dehydrators has revolutionized the way food is preserved. As demand for dried foods increases, manufacturers are integrating automation technologies to enhance efficiency and consistency. This article explores how automation in industrial food dehydrators optimizes the food dehydration process.

1. Understanding Automated Dehydration

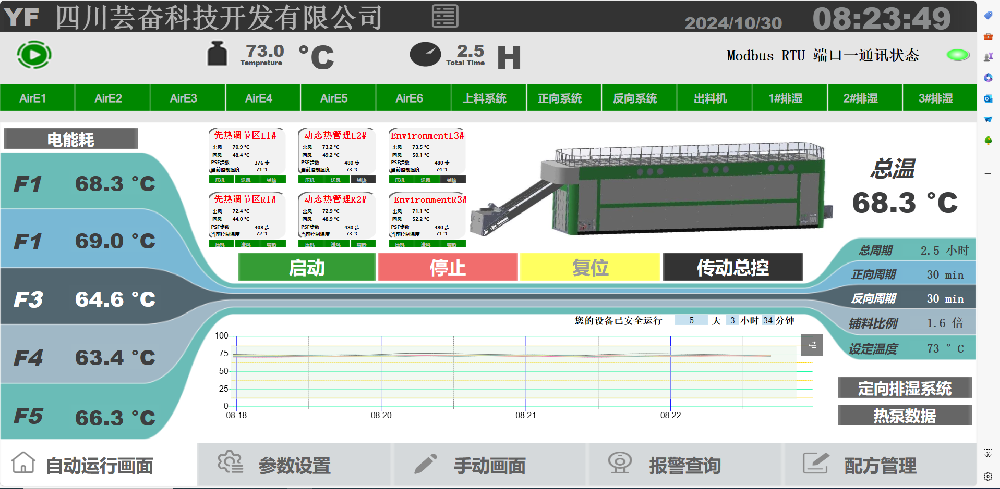

Automated food dehydrators utilize advanced control systems to regulate temperature, humidity, and air circulation during the dehydrating process. These systems can be programmed for specific products, ensuring optimal drying conditions tailored to the needs of various foods, such as fruits, vegetables, and meats.

2. Benefits of Automation

One of the key advantages of automation in food dehydration is increased operational efficiency. Automated systems reduce the need for manual monitoring as they continuously gather data on drying parameters. This minimizes human error and enhances product consistency. Additionally, automated dehydrators can operate in continuous cycle modes, allowing for higher throughput and faster processing times.

3. Integration of IoT Technology

Many modern industrial dehydrators are adopting Internet of Things (IoT) technology, which offers remote monitoring and control capabilities. This means operators can adjust settings, monitor progress, and troubleshoot problems from anywhere, significantly enhancing the flexibility of operations. IoT integration allows for data collection on various factors, leading to better decision-making and process improvements over time.

4. Energy Efficiency and Sustainability

Automation contributes to energy savings by optimizing energy usage during the drying process. Precise control over temperature and airflow helps to minimize energy waste while maintaining quality. Furthermore, many automated systems are designed to be more eco-friendly, reducing the carbon footprint associated with food dehydration.

5. Customization and Scalability

Customization is another significant aspect of automated industrial food dehydrators. Manufacturers can tailor machines to fit specific operational needs, accommodating various food types and production volumes. As businesses grow, these automated systems can easily scale, allowing for expanded production without sacrificing efficiency or product quality.

6. Conclusion

In conclusion, automation has transformed industrial food dehydrators into sophisticated machines capable of enhancing efficiency, consistency, and sustainability in food processing. As technology continues to advance, the future of food dehydration looks promising, offering businesses the tools to meet growing market demands while maintaining quality and reducing costs.