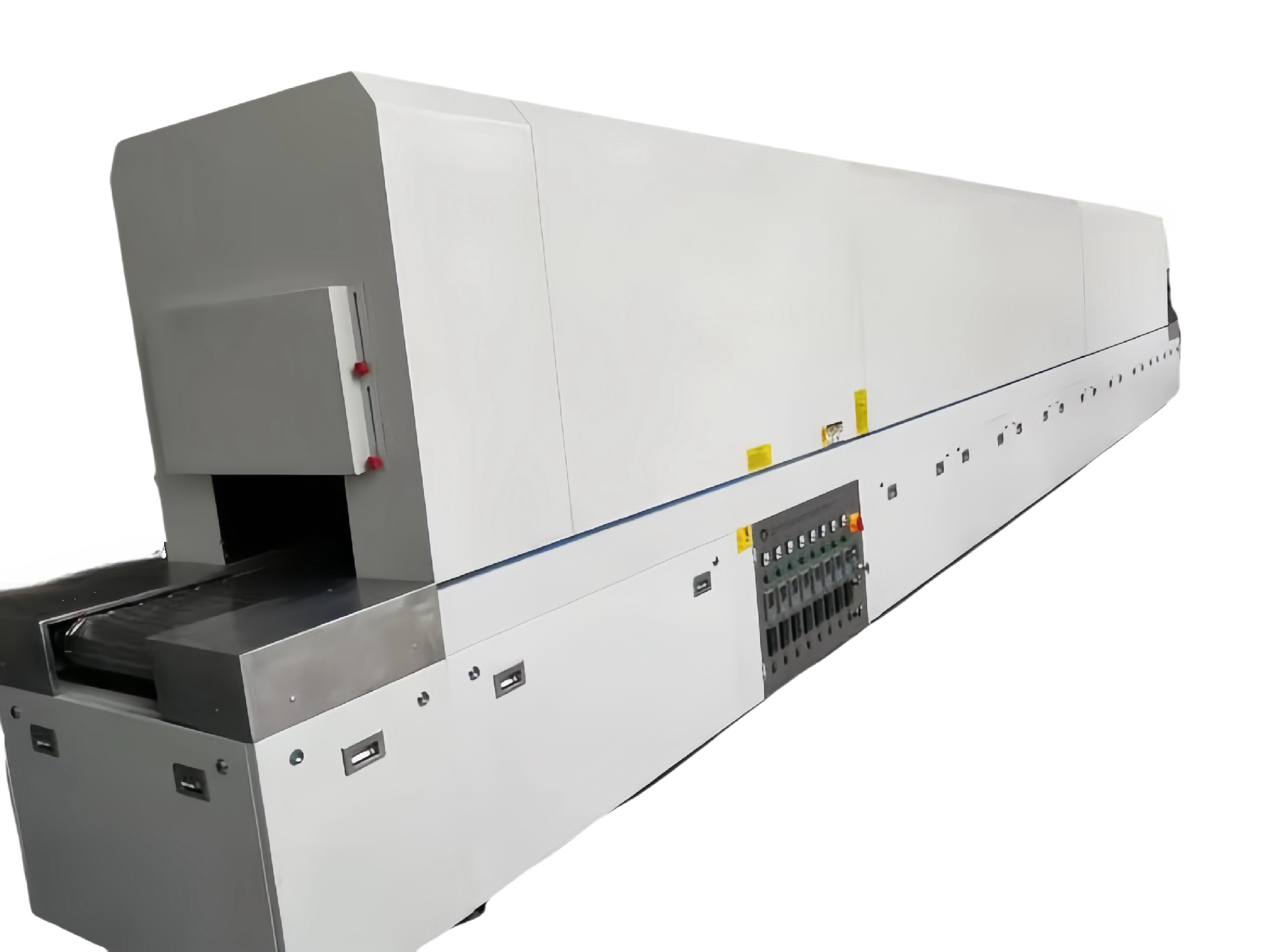

Tunnel dehydrator

Tu

a. What is a tunnel dryer?

Tunnel dryer is a continuous drying equipment. By placing the material on a conveyor belt or a material car, the material in the drying tunnel is gradually heated and dried as the conveyor or material car moves.This equipment is often used in large-scale production lines in the food, medicine, chemical and other industries, and can efficiently carry out continuous drying of large quantities of materials.

b. Why do we need a tunnel dryer?

Tunnel dryers can greatly improve production efficiency and are suitable for large quantities of materials that cannot be tumbled and need to be dried continuously.It can ensure the uniformity and quality of material drying, while reducing labor intensity and operating costs, and is suitable for modern industrial production needs.

c. What are the benefits of tunnel dryers?

①High drying efficiency, suitable for large-scale continuous production; ②Uniform drying, stable product quality; ③Low energy consumption, low operating cost; ④Easy to operate, high degree of automation; ⑤Wide range of application, can handle a variety of materials; ⑥Reduce manual operation and improve production safety.

d. What are the industrial uses of tunnel dryers?

It can be used for drying biscuits, medicines, chemical raw materials, electronic components, food drying, drying and sterilization of medicines, drying of chemical products, etc.

e. What is the working principle of the tunnel dryer?

The working principle of the tunnel dryer is to place the material on a conveyor belt or a material car, which brings the material into the drying tunnel, heats the air through the heating system, and then evenly distributes the hot air into the drying tunnel through the ventilation system to evaporate the moisture on the surface of the material. The wet air is discharged through the dehumidification system, and the dried material is output through the conveyor belt.

f. What are the different components of the tunnel dryer?

Conveyor belt, heating system, ventilation system, dehumidification system, temperature and humidity control system, control panel and drying tunnel body structure.

g. How are tunnel dryers classified?

①According to the heating method, it is divided into electric heating, air energy heating, steam heating and gas heating; ②According to the type of conveyor belt, it is divided into mesh belt type and plate belt type; ③According to the operation mode, it is divided into continuous type and intermittent type.

h. What are the important factors affecting the drying time of the tunnel dryer?

The initial moisture content of the material, the type and shape of the material, the temperature and humidity in the drying tunnel, the air flow rate, the conveyor belt speed, etc.i. What is the capacity of the tunnel dryer? The capacity of the tunnel dryer varies from several hundred kilograms to several tens of tons depending on the model and specifications of the equipment.j. What is the drying time of the tunnel dryer? The drying time of the tunnel dryer varies depending on the type of material and the initial moisture content, generally ranging from tens of minutes to several hours.k. Does the tunnel dryer require a large installation space? Yes, the tunnel dryer requires a large installation space.L. How to clean and maintain the tunnel dryer? ① Clean the conveyor belt, heater and ventilation system regularly to prevent material residue and blockage; ② Check the temperature and humidity control system and dehumidification system regularly to ensure the normal operation of the equipment.