Industrial Belt dehydrator

a.Please describe the function of a belt dehydrator.

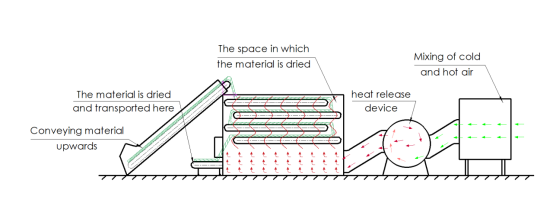

① schematic :

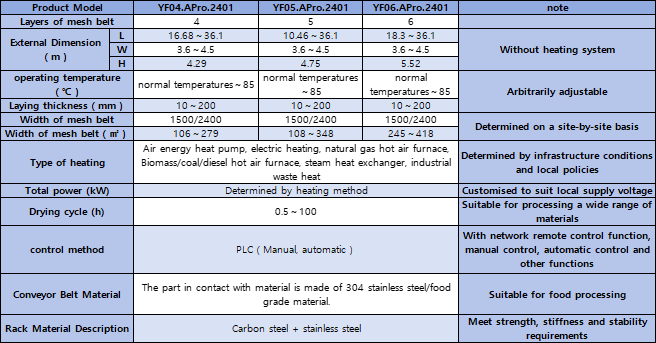

② Specification sheet :

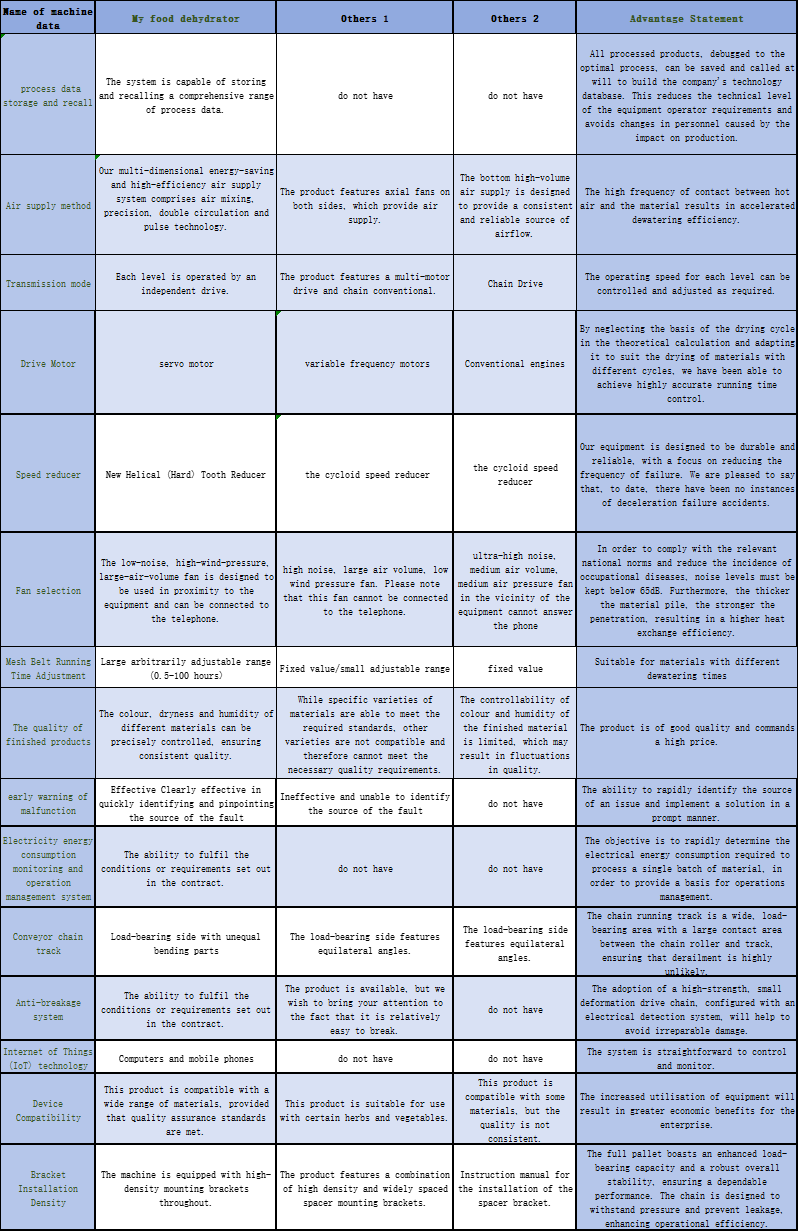

③ The product's most attractive features :

Belt dehydrators are highly efficient, continuous band dryer that are widely used in a variety of industries, including food, chemical, pharmaceutical and more, for the mass production of strip, block and granular materials drying.

b.What are the benefits of Industrial Belt dehydrator?

The Belt dehydrator boasts a highly efficient continuous drying capacity, making it an ideal choice for large-scale production environments. The machine is capable of handling a variety of materials and ensuring uniform drying. The product is simple and straightforward to operate and maintain. Its compact structure and small footprint make it easy to install and operate. Furthermore, the dehydrator boasts high energy efficiency, making it an environmentally conscious choice. The belt dehydrator is suitable for a wide range of materials, including fruits, vegetables, herbs, granules, feed, and more. It maintains the physical and chemical properties of the material, improving product quality and productivity.

The belt dehydrator has a fast drying speed, low energy consumption, and good product quality. It can be adjusted according to the specific drying requirements of different materials.

c.What are the industrial uses of Industrial Belt dehydrator?

Mesh belt dehydrators are a versatile piece of equipment, used in a wide range of fields. They are utilised in a number of sectors, including the pharmaceutical, food, chemical and agricultural industries.

d.What is the working principle of a Industrial Belt dehydrator?

The belt dehydrator operates on the principle of continuous drying using hot air. The material is evenly distributed across the mesh belt via the feeder, where it is then conveyed slowly through the dehydrator. The heating system is responsible for converting the pure cold air into pure hot air, which is then circulated under the action of the fan to flow through the materials on the mesh belt. Once in contact with the materials, the hot air removes moisture, thereby initiating the drying process.

e.What are the different components of Industrial Belt dehydrator ?

The system comprises the following components: feeding/loading system, drying chamber (mesh belt), heating system, circulation system, moisture removal system, discharging system, control system.

f.What types of belt dehydrators are available?

We offer two types of belt dehydrators: a single-layer mesh belt dehydrator and a multi-layer mesh belt dehydrator.

g.Please advise on the key factors influencing the drying time of the belt dryer..

The following factors must be taken into account when drying materials:

1. Type of material to be dried (organizational structure)

2. Thickness of material spreading

3. Humidity of circulating air

4. Speed of mesh belt

5. Temperature of hot air

6. Initial moisture content of material

7. Ratio of raw material to dried product by weight

h.Could you kindly clarify the capacity of a belt dehydrator?

Belt dehydrator capacity varies by model and application, typically ranging from a few hundred kilograms to several tons per hour.

i.Could you kindly let me know the drying time for a belt dehydrator?

The drying time of a belt dehydrator is contingent upon a number of factors, including the type of material, thickness, initial moisture content and drying temperature. The typical drying time range is between 20 minutes and 20 hours. The specific time must be adjusted and optimised in line with the characteristics of the material and production requirements in order to achieve the best drying effect.

j.Are belt dehydrators a viable option for small businesses?

The mesh belt dehydrator is suitable for all kinds of enterprises, and can be customized according to the production scale required by the enterprise or planned according to the product positioning of the enterprise.

k.Please advise on the cleaning and maintenance requirements for the belt dehydrator.

It is important to regularly clean the inside of the conveyor belt and drying chamber to prevent material residue and dust accumulation.

worn or damaged parts should be checked and replaced as necessary.

The transmission parts should be lubricated to ensure smooth operation.

The electrical system and controller should be regularly checked to ensure they are working correctly.

The ventilation system should be checked regularly to ensure it is unobstructed and maintaining the correct drying temperature and humidity.

The temperature and humidity sensors should be calibrated regularly.