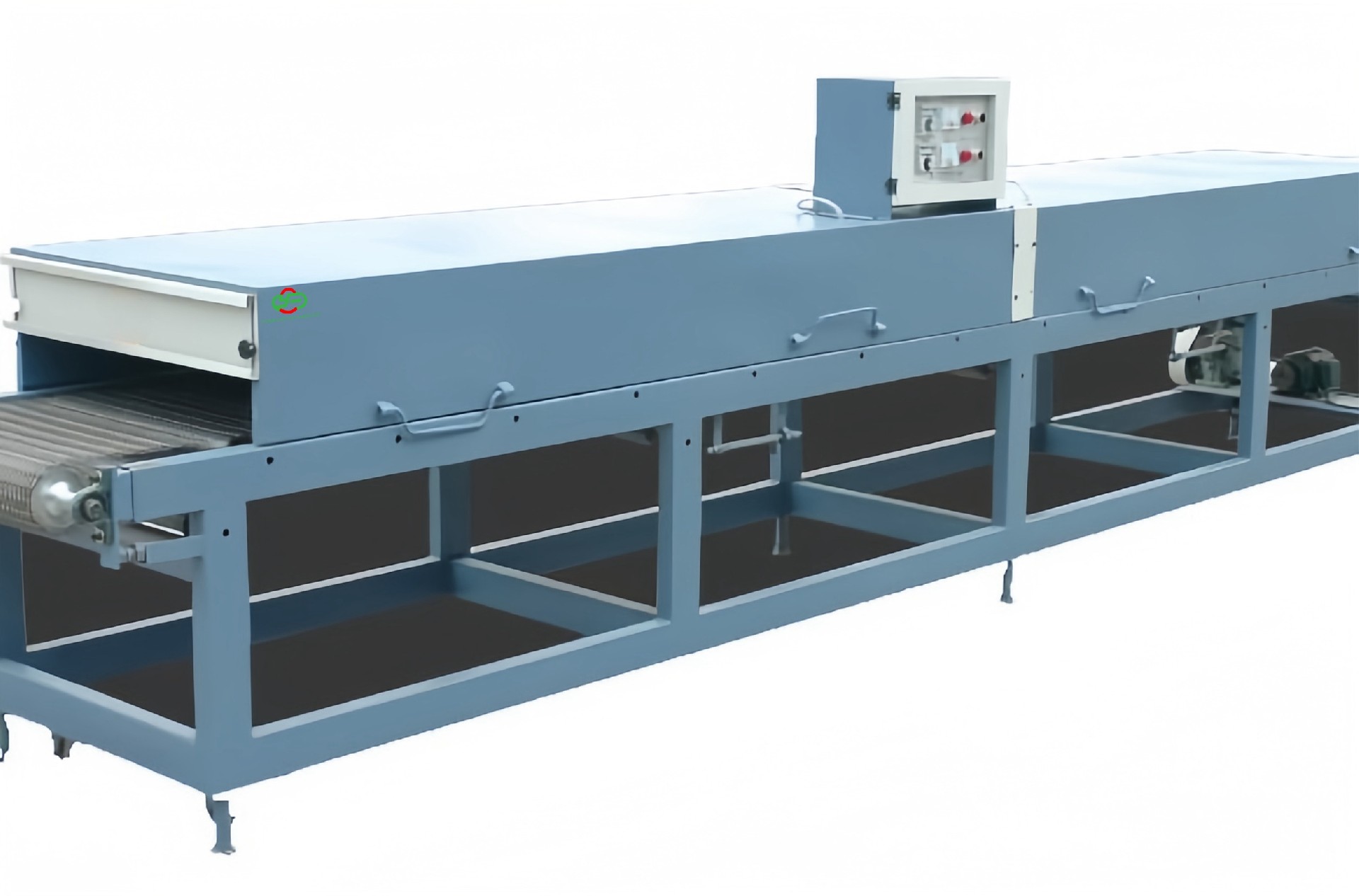

Infrared dehydrator

a.Please describe the function and purpose of an infrared dehydrator.

An infrared dehydrator is a piece of equipment that uses infrared radiation to dry materials. Infrared radiation penetrates the surface of the material, enabling the rapid evaporation of internal moisture and resulting in highly efficient drying.

b.Please explain the rationale behind the need for an infrared dehydrator.

The infrared dehydrator has become a vital piece of equipment in many industries thanks to its numerous advantages. These include high-efficient energy utilisation, uniform drying, precise temperature control, shorter drying times, energy saving and environmental protection, reduced space occupation, a wide range of applications and improved product quality.

c.What are the advantages of an infrared dehydrator?

The product has the following advantages:

1. It dries quickly, uses little energy and heats evenly, preventing the surface of the material from hardening and deteriorating.

2. It penetrates deeply into the material, enabling water to evaporate rapidly, thus improving production efficiency and product quality while maintaining the original quality of the material and nutrients.

3. It is simple to operate and maintain.

4. It is suitable for a wide range of materials and applications, including food, chemicals, pharmaceuticals, textiles and other industries. It is a widely used product in a number of different industries, including food, chemical, pharmaceutical, textile and more.

d.Please describe the operational principles of an infrared dehydrator.

The material is dried using infrared radiation, which is a form of heat energy. The infrared radiation produced by the infrared radiator penetrates the surface of the material, where it acts directly on the water molecules inside to make them vibrate and generate heat. This process warms the water inside the material and speeds up the evaporation process, which in turn achieves the desired drying effect.

e.What are the different components of an infrared dehydrator?

The system comprises an infrared emitter, drying chamber, conveyor belt, temperature control system, moisture removal system and control panel.

f.Please provide an overview of the types of infrared dehydrators that are currently available?

①Near Infrared Dryer; ②Medium Infrared Dryer; ③Far Infrared Dryer; ④Cabinet Infrared Dryer; ⑤Tunnel Infrared Dryer

g.Please advise on the key factors influencing the drying time of infrared dehydrators?

The initial moisture content of the material, the thickness of the material, the infrared wavelength and energy density, the design of the dehydrator, and the operating parameters and environmental conditions are the key factors to be considered.

h.Please advise as to the capacity of the infrared dehydrator.

Infrared dehydrators are available in a wide range of capacities, from a few kilograms for small laboratory equipment to several tons per hour for large industrial equipment.

i.Could you kindly let me know the drying time of an infrared dehydrator?

The drying times for infrared dehydrators are dependent on a number of factors, with typical drying times ranging from a few minutes to several hours. The precise drying time will depend on the material in question, the design of the equipment and the operating conditions.

j.Are infrared dehydrators a viable option for small businesses?

Infrared dehydrators are an optimal solution for small businesses, offering a combination of low energy consumption, compact design, and straightforward operation.

k.Please advise if an infrared dehydrator requires a large installation space.

The compact design of our small and medium-sized infrared dehydrators makes them ideal for small businesses and sites with limited space. In contrast, larger infrared dehydrators necessitate a more expansive installation area and are well-suited to large-scale, continuous production.

l.Please advise on the cleaning and maintenance requirements for an infrared dehydrator.

It is important to regularly clean the dust and sundries in the radiator and drying chamber to ensure optimal heating efficiency and drying effect.

It is also essential to regularly check and clean the conveyor belt to prevent material residue from affecting the operation. It is also recommended that moving parts are lubricated in order to prevent wear and tear.

m.Please describe the operational principles of an infrared dehydrator.

The infrared dehydrator employs infrared radiation to directly heat the material, enabling a rapid, efficient and uniform drying process.