Industrial Belt dehydrator

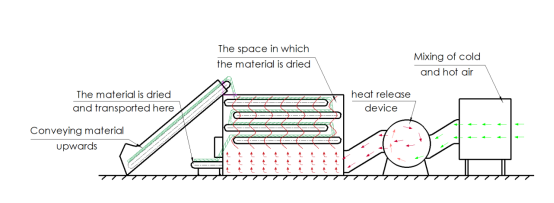

schematic

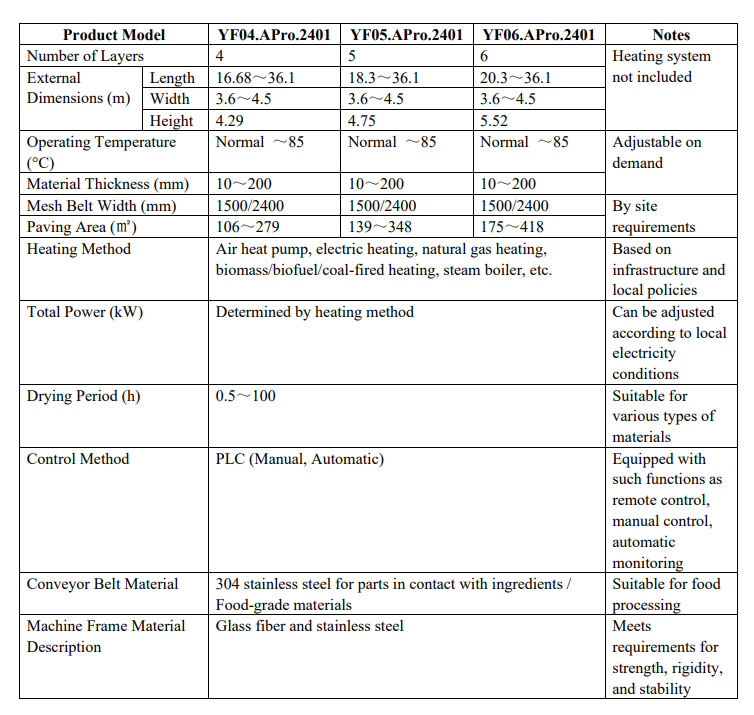

Specification

Belt dryer is a high-efficiency, continuous drying equipment, widely used in food, chemical, pharmaceutical and other industries, for mass production of strip, block and granular materials.

b. What are the benefits of belt dryer?

①Belt dryer has high-efficiency continuous drying capacity, suitable for large-scale production; ②Can handle materials in various forms to ensure uniform drying; ③Simple operation and convenient maintenance; compact structure and small footprint; ④Low energy consumption and energy saving; ⑤Suitable for drying materials such as fruits and vegetables, medicinal materials, and granular feed; ⑥Maintain the physical and chemical properties of materials, improve product quality and production efficiency; ⑦Fast drying speed, low energy consumption, and good product quality; ⑧Can adjust temperature, air volume and conveying speed according to the drying requirements of different materials.

c. What are the industrial uses of belt dryer?

Net belt dryers are used in many fields. They are pharmaceutical industry, food industry, chemical industry, agriculture, etc.

d. What is the working principle of belt dryer?

The working principle of belt dryer is to use hot air to continuously dry materials. The material is evenly spread on the mesh belt through the feeder, and the mesh belt moves slowly in the dryer. Pure cold air is converted into pure hot air through the heating system, and circulates under the action of the fan, passing through the material on the mesh belt. After the hot air comes into contact with the material, it takes away the moisture in it and realizes the drying process.

e. What are the different components of the belt dryer?

Feeding/loading system, drying chamber (mesh belt), heating system, circulation system, dehumidification system, discharging system, control system.

f. What types of belt dryers are there?

① Single-layer mesh belt dryer; ② Multi-layer mesh belt dryer

g. What are the important factors affecting the drying time of the belt dryer?

① Type of material to be dried (organic structure); ② Material thickness; ③ Humidity of circulating air; ④ Mesh belt speed; ⑤ Temperature of hot air; ⑥ Initial moisture content of the material; ⑦ Dryness ratio of the material.

h. What is the capacity of the belt dryer?

The capacity of the belt dryer varies depending on the model and purpose, usually ranging from several hundred kilograms to several tons per hour.

i. What is the drying time of the belt dryer?

The drying time of the belt dryer depends on factors such as the type, thickness, initial moisture content and drying temperature of the material. Usually, the drying time can range from 20 minutes to 20 hours. The specific time needs to be adjusted and optimized according to the characteristics of the material and production requirements to achieve the best drying effect.

j. Is the belt dryer suitable for small enterprises?

The net belt dryer is suitable for all kinds of enterprises and can be customized according to the production scale required by the enterprise or planned according to the product positioning of the enterprise.

k. How to clean and maintain the belt dryer?

① Clean the conveyor belt and the inside of the drying chamber regularly to prevent material residue and dust accumulation; ② Check and replace worn or damaged parts; ③ Lubricate the transmission parts to ensure smooth operation; ④ Regularly check the working status of the electrical system and controller; ⑤ Ensure that the ventilation system is unobstructed and maintain the appropriate drying temperature and humidity; ⑥ Regularly calibrate the temperature and humidity sensors.