1. Introduction to Flash Dryer

It is mainly used to dehydrate pasty, filter-cake, high-viscosity, and high-moisture materials. Pasty material from the spiral feeder into the dehydrator, for the high-speed rotation of the stirring paddle, block material is quickly crushed under the strong action of collision, friction and cutting force. The crushed material is dehydrated by being fully in contact with hot air. The dehydrated product is in the form of powder.

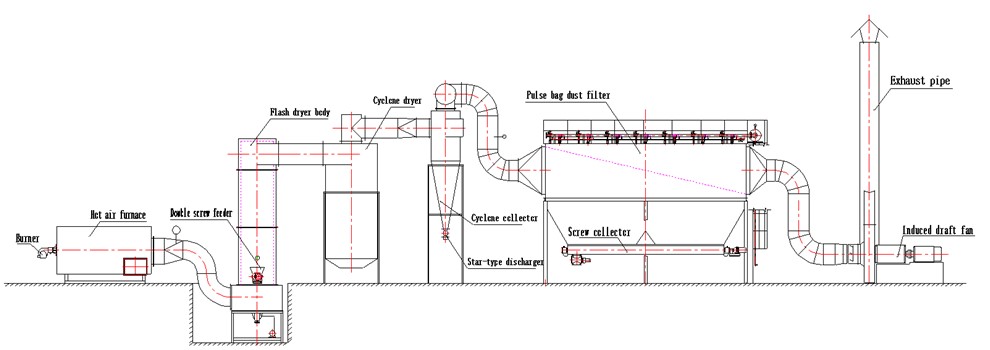

2. Equipment composition:

This machine is mainly composed of blower, heating device, quantitative feeding machine, dehydration host, collector (cyclone collector and bag filter), discharger, air supply pipeline, induced draft fan and electrical control cabinet and other components.

3. Working principle:

The fresh air sent in by the blast is heated by the heating device and then evenly enters the dehydrating chamber through the hot air distributor at the bottom of the main machine to form a fierce vortex. The hot air fully contacts and strongly collides with the wet materials quantitatively sent into the drying chamber by the feeder. The water film attached to the surface of the materials is continuously evaporated under the action of hot air and mechanical crushing. At the same time, the surface area of the materials is continuously increased under the action of mechanical crushing force, which strengthens the mass transfer and heat transfer of the materials in the hot air, so that the water evaporates more quickly. and the fine particles are carried upward with the rotating airflow in the main machine room and then continue to dry. The larger particles are thrown to the surrounding wall under the combined action of centrifugal force and the classification ring and fall back to the bottom along the main machine wall to re-participate in the above process. The dehydrated materials enter the cyclone collector with the airflow from the upper outlet of the main machine to separate from gas. A small amount of fine dust enters the dust filter device through the induced draft fan. The tail gas after capture and purification is discharged.

4. Applicable materials

(1) Organic matter: atrazine (pesticide insecticide), lauric acid septum, benzoic acid, benzoic acid, fungicidal dan, sodium oxalate, cellulose acetate, organic pigments, etc.

(2) Dyes: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

(3) Inorganic substances: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, zinc sulfate, zinc carbonate basic, antimony trioxide, various metal hydroxides, various heavy metal salts, and synthetic cryolite.

(4) Food: Soy protein, gelatinized starch, distiller's grain, wheat sugar, wheat starch, etc.

5. Specifications

Type | GXS-2 | GXS-4 | GXS-6 | GXS-8 | GXS-10 | GXS-12 | GXS-16 | GXS-18 |

Inner Diameter(mm) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 1800 |

Air Volume(m³/h) | 350~500 | 1150~2000 | 2450~4500 | 4450~7550 | 7000~12500 | 10000~20000 | 18000~36000 | 28200~56500 |

Moisture Evaporation(kg/h) | 12~17 | 40~70 | 80~150 | 150~250 | 230~480 | 300~600 | 600~1000 | 1000~1500 |

Max. Installed Capacity (kW) | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

Max. Height (m) | 4 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

Occupying Area(m2) | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. Moisture evaporation is the amount of water evaporated per hour when the inlet air temperature is 200 degrees Celsius and the outlet air temperature is 80 degrees Celsius.

2. Provide tailor-made service.

3. The installed capacity above is the standard package. The power packages can be significantly reduced according to the different material's moisture

6. Sketch Map