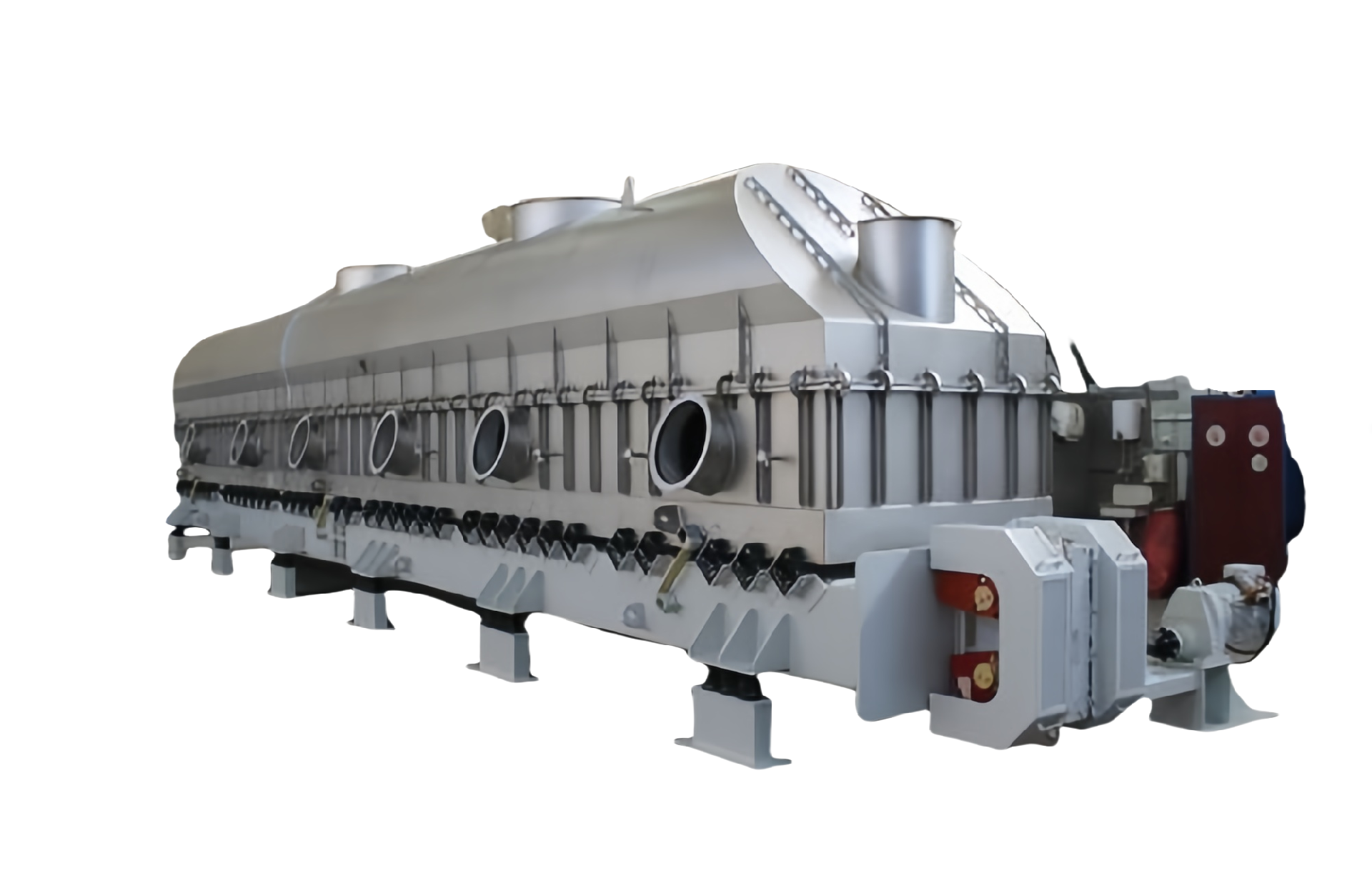

Fluidized bed dehydrator

a. Please describe the function and operation of a fluidized bed dehydrator.

A fluidized bed dehydrator is a piece of equipment used for the drying of materials. It achieves the drying process by placing granular or powdered materials in a hot air stream, thus suspending the materials in the air stream.

b. Please explain the rationale behind the need for a fluidized bed dehydrator.

Fluidized bed dehydrators are a popular choice in industrial production due to their ability to dry large quantities of materials rapidly and consistently, making them particularly well-suited to applications with stringent drying quality and efficiency requirements. It not only enhances production efficiency but also guarantees product quality.

c. Please outline the advantages of using a fluidized bed dehydrator.

The drying system offers the following key benefits:

1. Fast drying speed

2. Uniform drying

3. Large capacity

4. Low energy consumption

5. Simple operation

6. High degree of automation

7. Adaptable to different materials with adjustable operating parameters

8. Strong applicability

d. Please describe the industrial applications of fluidized bed dehydrators.

Fluidized bed dehydrators are a highly versatile piece of equipment, with a wide range of applications across numerous industries, including chemical, pharmaceutical, food, and building materials.

e. Could you kindly elaborate on the operational principle of the fluidized bed dehydrator?

The Fluidized Bed dehydrator operates on the following principles:

1. Hot air is evenly distributed into the drying chamber via the distribution board, suspending the material in the air flow.

2. The material is fully exposed to the hot air, rapidly evaporating the water to achieve the drying process.

3. The dried material is discharged through the appropriate device, while the wet air is expelled through the exhaust system.

f. Please describe the various components that comprise a fluidized bed dehydrator.

The product features a feeding system, distribution plate, drying chamber, heating system, airflow distributor, discharge system, exhaust system and control system.

g. Please advise on the classification of fluidized bed dehydrators.

The heating method can be divided into two categories: direct and indirect.

The mode of operation can be divided into two categories: continuous and intermittent.

The form of structure can be divided into two categories: vertical and horizontal.

h. What are the key factors influencing the drying time of fluidized bed dehydrators?

The initial moisture content of the material, the size and shape of the material particles, the inlet temperature, the airflow velocity, the thickness of the material bed and the operating parameters of the equipment all have an impact on the process.

i.What is the capacity of the fluidized bed dehydrator?

The capacity of a fluidised bed dehydrator is dependent on the specific model and specifications of the equipment in question. It can typically handle materials ranging from a few kilograms to several tons.

j. Could you kindly let me know the drying time for the Fluidized Bed Dehydrator?

The drying time for a given material will depend on the type of material and its initial moisture content. In general, drying times will range from a few seconds to several minutes.

k. Please advise if a large installation space is required for the fluidized bed dehydrator.

The installation space required for a fluidized bed dehydrator is dependent on the specific model and specifications of the equipment in question.

The smaller fluidised bed dehydrator has a relatively compact footprint, while the larger model requires more installation space.

l. Please advise on the cleaning and maintenance requirements for a fluidized bed dehydrator.

It is important to regularly clean the distribution board, drying chamber and exhaust system to prevent material residue and clogging. Furthermore, it is essential to regularly check and replace the wearing parts to ensure the optimal operation of the equipment.