Paddle dehydrator

a.Please describe the function and purpose of a paddle dehydrator.

A paddle dehydrator is a highly efficient and energy-saving indirect conduction heating drying equipment.

The rotating paddles inside the machine ensure that all the materials are fully contacted with the heated paddles and cylinder wall, allowing for uniform drying through constant stirring.

b.Please explain the rationale behind the decision to use a paddle dehydrator.

The paddle dehydrator offers a number of advantages in industrial production, including wide applicability, high efficiency and energy saving, a good drying effect, environmental friendliness, easy operation and maintenance.

The paddle dehydrator is the ideal solution for the efficient and uniform drying of a wide range of materials, particularly those with high moisture content or high viscosity.

c.What are the advantages of paddle dehydrators?

The product boasts a number of advantages, including high efficiency and energy saving, wide adaptability, easy operation and maintenance, environmentally friendly, economical and safe operation, and many other benefits.

It also features high heat transfer efficiency and low energy consumption, as well as a compact footprint.

d.Please describe the industrial applications of paddle dehydrators.

The paddle dehydrator is suitable for a wide range of industrial applications, including those in the chemical, pharmaceutical, food, environmental protection, minerals, petrochemical, agricultural and animal husbandry industries.

e.Could you kindly elaborate on the operational principle of the paddle dehydrator?

The paddle dehydrator employs a combination of indirect heating and mechanical stirring to ensure that the wet material is fully in contact with the heating surface in the cylinder body, thereby achieving efficient and uniform drying.

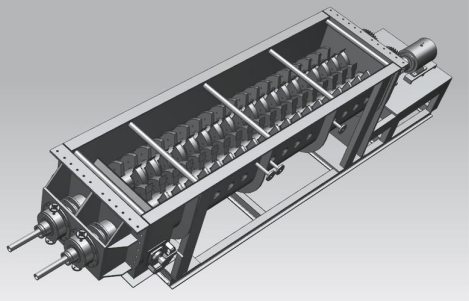

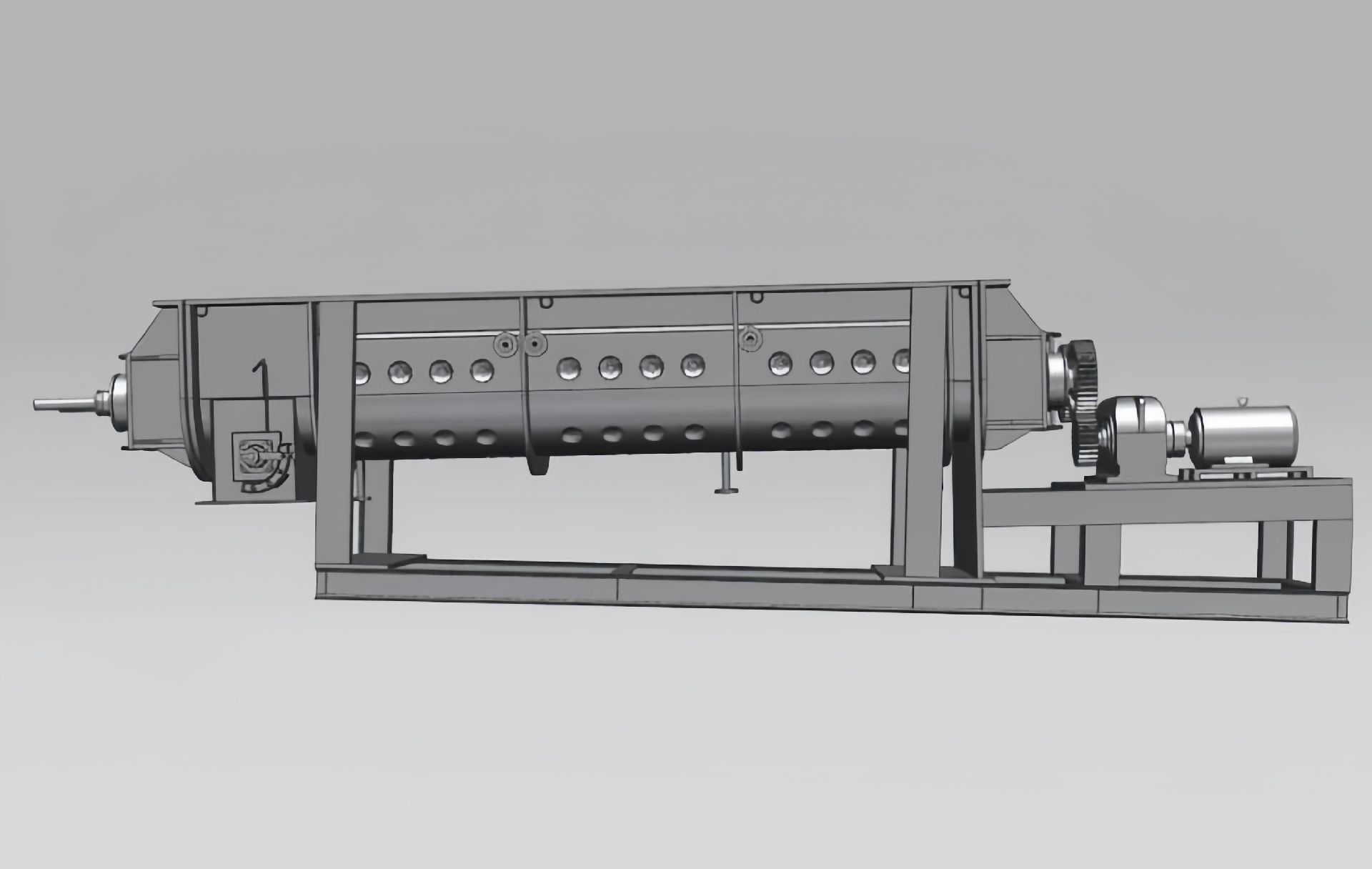

f.Please describe the various components of a paddle dehydrator.

The product comprises a cylinder, a hollow paddle, a rotor, a heating system, an inlet and outlet, an exhaust system, a motor and reducer, a control system and other components.

g.What types of paddle dehydrators are available?

We offer a range of paddle dehydrators to suit your specific needs.

Our product line includes:

1. Single Shaft Paddle dehydrator

2. Double Shaft Paddle dehydrator

3. Vacuum Paddle dehydrator

4. Atmospheric Pressure Paddle dehydrator

5. Pressurized Paddle dehydrator

h.Please advise on the key factors influencing the drying time of paddle dehydrators.

The following factors should be taken into account:

1. Material characteristics

2. Equipment parameters

i.Please advise the capacity of the paddle dehydrator.

Paddle dehydrators are available in a wide range of capacities. The specific capacity of a given dehydrator depends on a number of factors, including the size of the equipment, the characteristics of the material being dried, the operating parameters, the design configuration, and other variables.

j.Could you kindly let me know the drying time for the paddle dehydrator?

The drying time of the paddle dehydrator is dependent on a number of factors, including the characteristics of the material being dried, the parameters of the equipment being used and the operating conditions. The drying time can vary considerably, typically ranging from 30 minutes to six hours.

k.Please clarify the distinction between a paddle dehydrator and a vacuum dehydrator.

The paddle dehydrator is designed for large-scale, high-efficiency drying of conventional materials. The vacuum dehydrator is suitable for heat-sensitive, easily oxidised and high value-added materials.

l. Please advise if a paddle dehydrator requires a significant amount of installation space.

The three categories of equipment are suitable for different purposes and spaces. Small equipment is compact and ideal for laboratory or small-scale production. Medium-sized equipment is well-suited to small and medium-sized enterprises. Large equipment requires more space and is best suited to large-scale industrial production.

m.Please advise on the cleaning and maintenance requirements for the paddle dehydrator.

1. Regular cleaning: following each use, the residual material in the machine should be cleaned up in a timely manner to prevent the accumulation of dirt.

2. Lubrication and maintenance: regular checks and lubrication of the transmission components should be carried out to ensure smooth operation. It is important to regularly check the seals to prevent leakage and replace them if necessary.

n.Could you kindly elaborate on the operational mechanics of a paddle dehydrator?

The paddle dehydrator employs a rotating paddle mechanism to facilitate drying through stirring action, ensuring optimal contact between the materials and both the heated paddles and the cylinder wall.