1. Introduction to Vibrating Fluid Bed Dryer

It is applied to dehydrate and cool of powdery and granular materials in chemical, pharmaceutical, food, dehydrated vegetables, grain, mineral and other industries.

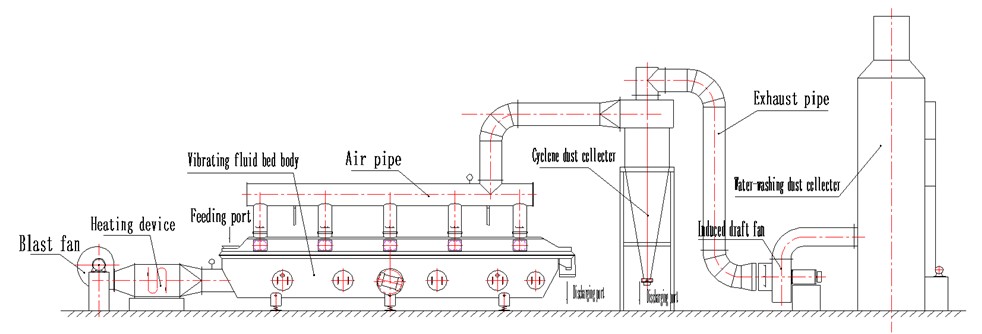

2. Equipment Composition

This machine is mainly composed of blower, heating device, vibrating fluid bed body, collector (cyclone collector or bag filter), discharger, air supply pipeline, induced draft fan and electrical control cabinet.

3. Working principle

The material enters the machine from the feed port. Under the action of vibration force, the material is thrown along the horizontal fluidized bed and moves forward continuously. After the hot air passes through the fluidized bed upwards and exchanges heat with the wet material, the wet air is discharged from the exhaust port after dust removal by the cyclone separator, and the dry material is discharged from the discharge port. The fluidization is uniform without dead gaps and blow-through phenomena, and evenly dehydrated and cool products can be obtained. It has good adjustability and wide application. The thickness of the material layer, the moving speed in the machine and the full amplitude change can all be adjusted steplessly. The damage to the ingradient surface is small, and it can be used for drying fragile materials; irregular material particles do not affect the working effect. The fully enclosed structure effectively prevents cross infection between materials and air and keeps the working environment clean. It has high mechanical and thermal efficiency and a good energy-saving effect because it can save 30-60% more energy than general dehydrating devices.

4. Applicable materials

Citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distiller's grains, seeds, slag, sugar, etc.

5. Specification

Type | Occupying Area(㎡) | Inlet Temp.(℃) | Outlet Temp.(℃) | Evaporation capacity (kg/h) | Vibration motor | |

Type | Power (kw) | |||||

ZLG3×0.30 | 0.9 | 70~140 | 40~70 | 20~35 | ZDS31-6 | 0.8×2 |

ZLG4.5×0.30 | 1.35 | 70~140 | 40~70 | 35~50 | ZDS31-6 | 0.8×2 |

ZLG4.5×0.45 | 2.025 | 70~140 | 40~70 | 50~70 | ZDS32-6 | 1.1×2 |

ZLG4.5×0.60 | 2.7 | 70~140 | 40~70 | 70~90 | ZDS32-6 | 1.1×2 |

ZLG6×0.45 | 2.7 | 70~140 | 40~70 | 80~100 | ZDS41-6 | 1.5×2 |

ZLG6×0.60 | 3.6 | 70~140 | 40~70 | 100~130 | ZDS41-6 | 1.5×2 |

ZLG6×0.75 | 4.5 | 70~140 | 40~70 | 120~140 | ZDS42-6 | 2.2×2 |

ZLG6×0.9 | 5.4 | 70~140 | 40~70 | 140~170 | ZDS42-6 | 2.2×2 |

ZLG7.5×6.0 | 4.5 | 70~140 | 40~70 | 130~150 | ZDS42-6 | 2.2×2 |

ZLG7.5×0.75 | 5.625 | 70~140 | 40~70 | 150~180 | ZDS51-6 | 3.0×2 |

ZLG7.5×0.9 | 6.75 | 70~140 | 40~70 | 160~210 | ZDS51-6 | 3.0×2 |

ZLG7.5×1.2 | 9 | 70~140 | 40~70 | 200~260 | ZDS51-6 | 3.0×2 |

6. Sketch Map